3PE Welded Steel Pipe ERW steel pipe

$400-850 /Ton

| Payment Type: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,DAF,DES,CFR,CIF,EXW,FAS,FCA,CPT |

| Min. Order: | 1 Ton |

| Transportation: | Ocean,Land |

| Port: | Tianjin,Shanghai,Qingdao |

$400-850 /Ton

| Payment Type: | L/C,T/T,D/P,D/A |

| Incoterm: | FOB,DAF,DES,CFR,CIF,EXW,FAS,FCA,CPT |

| Min. Order: | 1 Ton |

| Transportation: | Ocean,Land |

| Port: | Tianjin,Shanghai,Qingdao |

Brand: Youfa

Standard: Bs, Gb, Astm, Jis, Din, Api

Material: 10mowvnb, Cr-Mo Alloy, Crni Alloy, Stpa22-Stpa26, Api J55-Api P110, 16mn, Stb35-Stb42, Mo, A53-A369, 10cr9mo1vnb, Stpg42, Stba20-Stba26, Q195-Q345, Mn-V Alloy, 15nicumonb5, St35-St52, 10#-45#

Section Shape: Round

Place Of Origin: China

Application: Fluid Pipe, Structure Pipe, Boiler Pipe, Drill Pipe, Hydraulic Pipe, Gas Pipe, Oil Pipe, Chemical Fertilizer Pipe

Production Process: Cold Drawn

Certification: Bsi, Ce, Ul, Api

Special Tube: Api Pipe, Emt Pipe, Thick Wall Pipe

Whether Alloy: Is Alloy

Tolerance: ±1%, ±10%

Category: Welded Steel Pipe

Processing Service: Bending, Welding, Decoiling, Punching, Cutting

| Selling Units | : | Ton |

| Package Type | : | Exporting seaworthy standard or as request. |

| Picture Example | : |

|

The file is encrypted. Please fill in the following information to continue accessing it

The advantages of antiseptic pipe

1. Perfect impact resistance, friction resistance, shock resistance

2. High acid alkali salt resistance

3. High electrical-shock resistance

4. low oozing water rate

5. Long use time

3 Layer PE Coating Steel Pipe Technical Instructions

Structure of the 3PE coating steel pipe

Three layer PE coating anti-corrosive steel pipe carry out the standard of GB/T23257-2009 and DIN30670.

Structure:inner steel pipe,epoxy powder coating,middle layer of adhesive,outer layer of high density polyethylene

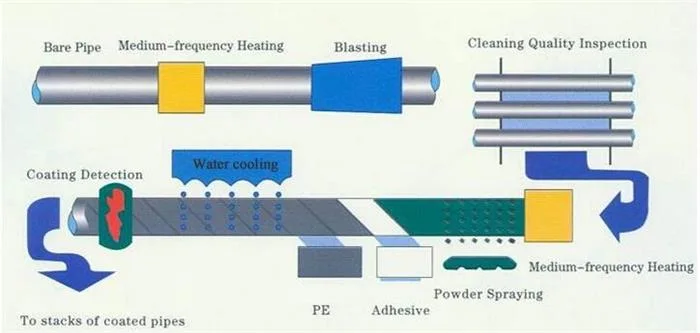

3PE coating manufacturing process

Production process

Steel pipe inspection→Steel pipe pre-heating→Steel pipe shot-blasting→Anchor pattern depth/Cleanness inspection→Steel pipe medium→frequency heating→Epoxy powder spraying→Adhesive coating→Polyethylene Wrapping-Water cooling to 60ºC below→Online electric spark→Pipe end treatment→Finished product inspection→Product marking→Certification sticking→In storage

Specification of Thickness of Anti-corrosive Coating Layer

| DN of steel pipe | Epoxy powder | Adhesive Layer | Minimum thickness of the coating(mm) | |

| Common Level(G) | Strengthen Level(S) | |||

| DN≤100 | ≥120 | ≥170 | 1.8 | 2.5 |

| 100 | 2.0 | 2.7 | ||

| 250 | 2.2 | 2.9 | ||

| 500≤DN<800 | 2.5 | 3.2 | ||

| DN≥800 | 3.0 | 3.7 | ||

Properties of the Epoxy Powder

| NO. | Item | Indexes |

| 1 | Size distribution(%) | 150μm oversize powder≤3.0 |

| 2 | Volatiles(%) | ≤0.6 |

| 3 | Density(g/m3) | 1.3-1.5 |

| 4 | Gel time(230ºC)/(S) | 15-30 |

| 5 | Fixed time(230ºC)/(min) | ≤3 |

Properties of Fusion Bonded Epoxy Coating

| NO. | Item | Indexes |

| 1 | Adhesive(grade) | ≤2 |

| 2 | Cathodic disbonding(65ºC,48h)/(mm) | ≤8 |

| 3 | Cathodic disbonding(65ºC,30h)/(mm)) | ≤15 |

| 4 | Counter bending(-20,2.5) | No cracks |

Properties of adhesive

| NO. | Item | indexes |

| 1 | Density (g/m3) | 0.920-0.950 |

| 2 | MFR(190ºC,2.16kg)/(g/10min) | ≥0.7 |

| 3 | Vicat softening point(ºC) | ≥90 |

| 4 | Brittle temperature(ºC) | ≤-50 |

| 5 | Oxidation induction time(OIT) | ≥10 |

| 6 | Moisture content(%) | ≤0.1 |

| 7 | Tensile strength(MPa) | ≥17 |

| 8 | Elongation at break(%) | ≥600 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.